-

Posts

1,234 -

Joined

-

Last visited

-

Days Won

185

Content Type

Profiles

Forums

Gallery

Everything posted by SnowStorm

-

Brake Rottors strange wear pattern

SnowStorm replied to David Toth's topic in Brakes, Chassis, Park Assist & Suspension

So we have thought - and I've done it a number of times. However, I soon noticed that you can shift to N, brake to a stop and still get a braking score - even 80 or 90 percent! The whirligig thingy is gone but you can get a high score as if regen happened normally. Has anyone else noticed this behavior? With more experimentation it seems that if you shift to N before taking you foot off the accelerator, you don't get a score. I need to try it some more to be sure. Question is, if you get a score after shifting to N, did it really use regen or did it just show the score as if regen had happened. I guess I'll have to try the two scenarios, jump out, touch the rotors to see if they heated up and hope I don't get burned! -

So is SE Sport FWD at MSRP of $28,255 the cheapest Escape hybrid? (That's about a $4k jump over the C-Max.) Love it that the "sport" model is hybrid only! The hybrid image has finally changed!

-

Basic SYNC radio replacement in 2016 SE

SnowStorm replied to ald16's topic in Audio, MyFord, Navigation & SYNC

Thanks for a great write-up. My radio is dead so rather than pay who knows how much to get it fixed I guess I should look at this option - it looks really nice. -

For general interest, here are some links that you may have seen before: WeberAuto video of transmission gears and motorsOld article about Ford's transmission assembly plant with a nice video of transmission assemblyI couldn't find the planetary gear system when I took mine apart - the WeberAuto video shows its location on the ICE input shaft. Its just about the smallest part of the whole thing! Amazing that all the torque from the ICE goes through that assembly not much bigger than a hockey puck. I can't get mine out because the motor rotors wont budge.

-

OK, bad choice of words. Just thinking that we, obviously, shouldn't have to adjust how we drive to make our cars last. It would be extremely difficult to stay out of EV and avoid regen or whatever Ford considers problematic. My guess on the variability of lifetime is that its more likely caused by variation in part tolerance than driving conditions. Ford's "Under certain driving conditions" might be true in a way but sounds rather like a cop-out statement - attributing the variability of failures to driving conditions. I'm also thinking that its not really a faulty bearing per se (as with race or rollers) but some part that has moved on the shaft after which the bearing is "faulty" since it is no longer positioned properly. An interference fit will always have a tolerance associated with it; tight and it lasts indefinitely, not tight enough and it goes 100k+, loose and it fails at 30k. Or the steel is defective or improperly selected and relaxes over time with tolerances still coming into play. Who knows.

-

Here's a list are of the parts replaced: CV6Z 9448 A :GASKET 1@13.02 5L7Z 7D285 A :SEAL - SPECIAL 2@13.68 5L7Z 7J324 A :RING 2@15.89 1S7Z 6379 AA :BOLT - HEX.HEAD 2@6.36 1S7Z 6379 AA :BOLT - HEX.HEAD 4@6.36 DG9Z 7550 A :DISC ASY - CLUTCH DG 1@142.55 DS7Z 19B596 A :KIT - AIR CONDITIONING SY 1@34.73 DL3Z 19B596 B :KIT 1@9.14 W711289 S300 :RIVET PLASTIC 3@5.25 VC 3DIL B :ANTI-FREEZE 3@13.32 FL 910S :KIT - ELEMENT & GASKET - OIL F 1@4.99 XT 7 QCFT :FLUID - TRANSMISSION :4@19.95 XO 5W20 BSP :MOTORCRAFT SAE 5W-20 SN SNP 5@2.95 The last and 3rd to last items are certainly ICE oil and filter which really bugs me since I had just changed oil and filter to Mobil 1 (as usual). Why change those? In asking about what was involved in the job, I was told that they also put in the latest "calibrations" which meant that it might shift differently until it learned my driving style (or some such comment). I don't see why any new software would need to be loaded but who knows. I also asked about the high voltage part of the job and was told it was a big deal - not sure what that meant. The person I normally talk to wasn't there when I picked up the car - I think he would have given more substantive answers. I wonder how many of these parts are truly required. They asked me about changing the clutch saying it was "recommended" so I said yes to that one. My old clutch looks fine (for all I know) except for a few scuff marks from, I suppose, metal parts that broke out of the hole.

-

Along with noise, one could periodically check the color of the fluid. If it still looks like new (clear with reddish tint) then there probably hasn't been much or any wear. When I changed my fluid at 154k miles it was rather black - lots of aluminum in it I guess. Since I had noise for, I think, at least 20-30k miles before the oil change, you should probably check every 5k miles. I can't find it now but I thought stratosurfer said his fluid looked OK. I don't think I would opt for a repair job. You might save $500+ on parts but there will be a lot more labor. Also, what do you do if you open it up and find wear and damage? You'll have to get a replacement anyway. In the TSB procedure the transmission was only repaired if there was no wear. It seems less risky to go with a low mileage transmission that doesn't have to be torn apart and reassembled - probably by someone whole never did it before. For sure, I wouldn't start down the repair route if my fluid wasn't clean.

-

Its interesting how Figure 1 in TSB 17-0039 shows the shaft protruding a bit past the ring. On my transmission the ring is out way past the end of the shaft. Looks like the assembly may have used an interference fit that didn't hold.

-

So do I! My donor car was a 2016. I just called Ford and, not surprisingly, was told that there was no program that would pay for the repair - but keep my receipts in case they initiated one in the future!

-

See description in post #56 above. At the end, it was most noticeable during EV around 30-40 mph with forward torque. Let off the accelerator and noise would go away. It was also there during regen. It wasn't loud - perhaps no more than normal tire noise at that speed. When ICE would start it was usually hard to tell if it went away - I think it at least dropped in intensity. There was an earlier time when I thought it didn't vary much with torque - I kept listening for that effect hoping it was just a CV joint. After rereading 14B07 it sounds like that is definitely my problem. I have wear patterns just like you see here in figure 3. The maddening thing is, I had Ford check my VIN when 14B07 was active and was told my car wasn't affected. Now it has failed with those exact results (only worse!). My view is that these transmissions were defective (design, manufacture, or both) and there is no need to blame driving style.

-

Brake Rottors strange wear pattern

SnowStorm replied to David Toth's topic in Brakes, Chassis, Park Assist & Suspension

So I went ahead and had the dealer replace the rear brakes so they could go ahead with the inspection. This "rusty" rotor "full contact" stuff has me irked. I could "need" new rotors every year from now on if I can't keep that mottled pattern at bay. I'm getting suspicious of a self serving scam. I could see requiring new brakes if the pads were really only hitting part of the rotor, leaving the rest truly rusty. But with this mottled pattern it looks like the pads contact the full face or the rotor but the rotors are rusting faster than they are getting worn down so little depression form. For all we know, that pattern may be acting like sand paper and creating more friction - hence, better brakes! Its getting more disgusting than my failed transmission - and could cost just as much in 9 years! I wanted the old parts from my car but didn't get them - apparently they forgot. My hope was to find a way to lightly "resurface" them. We need stainless rotors but it looks like only motorcycles and boat trailers are that lucky. Does anyone know anything about coated rotors? They are supposed to hold up better against rust. And what about break-in (or is it brake-in!) procedures to minimize the problem? -

Its the original - went 176k miles. But it was making noise since maybe 120k, maybe even before 100k but I never noticed. The noise was never very loud - you could easily ignore it. I've had tires make more noise. I only knew it was leaking fluid when I changed ICE oil and found that belly pan saturated.

-

Here are photos from my old transmission. Side that faces ICE. That 2" hole with the various seals next to it isn't supposed to be there! It leaks oil rather badly! Close up of hole - no idea where the seals came from. Wear channels on inside. End of shaft that made the hole. The bearing didn't seem to seat properly on its race. It seems like the gear is too far to the left or the race has moved to the right. Here's the complete shaft - except you can't see the bearing that is in previous photo. Note how teeth corners are gone from right side of left gear. Another shot of damaged gear. A number of the corners were scattered around inside the transmission! Its a bit scary to think I was driving around with all that carnage in there. Costs: Used transmission $1200 + $150 shipping + $200 for 1 year parts/labor warranty Installation labor $1400 Vibration damper "clutch" $142.55 Fluid $79.80 Anti-Freeze (I asked for a change in the ICE) $39.96 Various other parts $174.93 Engine oil (???) $14.75 Total parts $451.99 Shop supplies $30 (included brake job) Tax $25.55 Total for new transmission $3457.54 So, less than half that of new Ford transmission. Hope it lasts.

-

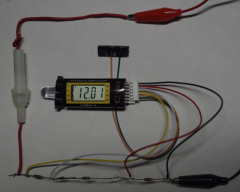

From the album: SS

-

The Enterprise is home and runs beautifully again! Absolutely silky quiet during EV, torque applied or not, and during regen. The old one has a "beautiful" 2 inch round hole facing the ICE where a shaft (transfer?) wore all the way through. Inside, there is a gear on the same shaft that wore a channel about 0.1 inch deep in the internal housing. Pictures are on the way. (Boy, is that thing heavy!)

-

Well, we get our car back tomorrow along with the old transmission which promptly gets torn apart. I'll let you know if I find a clutch in there! More seriously, I'll try and figure out what wore out (or what part was missing!?!?!) that allowed a gear to wear a hole clear through the side of the case. Ford really should do something for customers with such bizarre failures - we're not talking about a normal wear out mode here (at least I hope not!). As to oil, I have no answers to your questions but would wonder about heat dissipation (you can monitor temps of course) and possible electrical conductivity. The windings are insulated but there might be bare surfaces at the connectors. I'll try and figure that out during tear down. Again, I have no knowledge of the various oils - they might all be good insulators but there are voltages in the hundreds and possible transients above that.

-

Dealers sure do vary in attitude and accommodation - I'm lucky. When I asked about sourcing my own transmission, I was was told immediately that I certainly could. When I called with the donor VIN, the service tech went over to parts (while I waited on the phone!) and came back with the answer that the VINs of the donor car and my car both linked to the same Ford part number. I don't know if there is a way to check compatibility outside of using a dealer but I hope there is. My car is back together and ready to go but I won't be able to pick it up for some days yet. I'm getting the old transmission back so when I do, I'll open it up, take some pictures and give a report in a couple of weeks. When I pick it up, I'll try and ask some general questions about what all was involved in doing the swap.

-

Thought you had a C-Max, not a DeLorean!